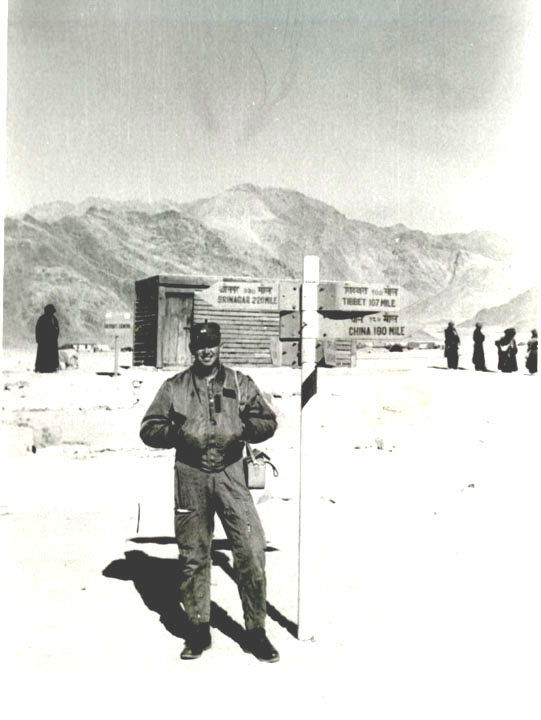

Locals at Leh International Airport. David Sutherland said it reminded him of "Big Stoop", the Mongolian in the Terry and the Pirates comic strip. Elevation at Leh is 10,000 feet. Mountains in the background go above 23,000 feet.

Signpost says: Srinagar 220 miles.

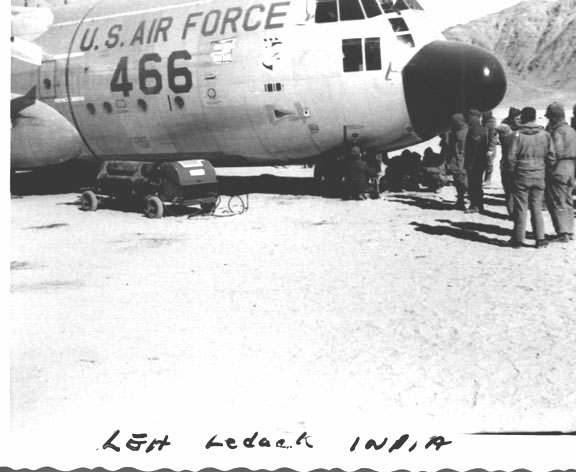

This photo of C-130 466 was taken at Leh International Airport, India, while it was undergoing nose gear replacement. Leh is in the Himalayan Mountains at an elevation of 10,000 feet.

This repair was in the winter under miserable working conditions. The PSP planks and canvas helped break the cold wind. Missing from this series is a photo that shows 466 being removed from the runway. After jacking up nose and putting a baggage cart under it, arranging hydraulic pressure for brakes, with a tractor to pull it backward down the hill, and about 100 Indian troops on ropes to swing the nose around, they cleared the runway. There she sat for several weeks while being temporarily repaired. (If you have a copy of that photo, please share it with us.) It looked like a bunch of ants moving a grasshopper.

The Indus River on the way to Leh.

Leh airfield from the air. Headed out toward river, note additional runway is wider than original.

During 90/270 degree procedure in the valley to get lined up with runway to land.

A C-130 landing at Leh.

C-130s parking/ offloading area at Leh.

A broader picture of the parking area at Leh.

A C-130 departing the Leh airport.

A C-130, 466, taking off. Photo taken by one of the maintenance men.

On first attempt to evacuate 466, nose steering was hooked up backward. While hydraulic lines were being changed, oxygen leaked down due to damage to lines, oxygen tanks were towed to aircraft, but connection at end of hose broke off. (Note: no nose gear door.) Returned next day with walk around bottles, replacement Navigator and replacement Chase Pilot.

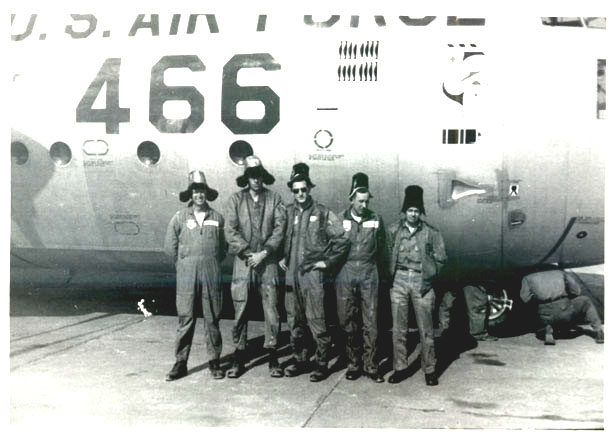

Pictured is the crew that evacuated 466 from Leh after the nose gear was replaced. Note maintenance personnel examining the nose gear. From left to right: David Sutherland, Al VanButen, Ray Lembke, Cecil Cheevers (Engineer) and Ssgt Alverson (Loadmaster), with their souvenir hats.

C-130 with flat tire and wind lifting left wing. Prop turned to avoid ground.

Training Squares were filled any time we could accomplish it and do our mission. Practiced formation flying to and from DZ, over Himalayas.

Who's on the other side?

I was on the first 39th TCS crew to arrive at new Delhi, India on Dec 27, 1962.

The other Squadrons had been in India since before Thanksgiving. India and China were having a Border war and the US sent a Squadron of C-130s to help India. At first they were evacuating wounded and refugees from the front areas back to New Delhi.

By the time I got there, the evacuation was about complete and we were helping build up the defenses in the Himalayas, by transporting men and material to Leh. Leh is on the Indus River, and would be the invasion route from China to India. The elevation of the airfield at Leh was over 10,000 feet; and the runway was perpendicular to the river and valley. Mountains around the valley were above 23,000 ft. The runway was approx. 4,000 ft. with an additional 1,000 ft. Extension, made of pierced steel planking (PSP). The extension did not blend in well with the original runway. Where they joined it was similar to jumping a street curb. The runway had about an 11 degree slope from the river going up.

The procedure was to fly over the mountains and let down in the valley using visual flight rules (VFR), fly down the valley approx. 1,000 ft. above terrain. Then fly outbound over the runway toward the river. Over the river make a 90 degree turn to the right then a 270 degree turn to the left; rolling out on runway heading across the river from the airstrip. Hugging the downward slope to the river, then start to flair for touchdown. All landing were made from the river going up slope; all takeoffs were the reverse, down slope and over river.

After takeoff; climbing turns over the valley until you could clear the mountains outbound. Again strictly VFR in the valley. My initial flights were with an Instuctor Pilot from 41st TCS and we aborted a couple of flights at the point to let down because it was solid clouds below. The Indian Air Force invited us to their Officers Club for New Year's Eve, and I was razzed by some of the bold pilots that got in those days we aborted. Which brought on the old saying “THERE ARE OLD PILOTS, AND THERE ARE BOLD PILOTS; BUT NOT MANY OLD BOLD PILOTS.”

There was no tower or control at Leh, pilots controlled themselves. Take off times were staggered and we flew quadrennial altitudes going and coming, which gave us vertical separation. We parked alongside the runway and shutdown engines for off loading. The material handling equipment was usually manpower. The natives were Mongolian looking dark skinned (that could be due to less frequent baths). There was a mud stucco looking hut that the boy would give you a cup of chi (strong tea). Not bad and it was hot. Our procedure was after parking to go get a cup of chi and smoke a cigarette, walk back to the airplane and crawl up to the flight deck and grab your oxygen mask and breath several times. They said the troops we were bringing up to Leh would be held there for a couple of weeks then moved on up to the 15,000 ft plus area. This allowed them to acclimate to the altitude.

When the 39th Squadron took over the operation from the 41st; Mike Washofsky was the scheduling officer . He would schedule himself to fly the next day and me (the Squadron Chief Pilot) to be the scheduling officer. Of course I would schedule myself to fly and him to be on the desk the next day. We had been talking about writing up a Standard Operations Procedure (SOP) concerning landings at Leh with a tailwind. I was on scheduling duty that day and we had decided: 1. no down Slope landings. 2. No landings when tailwinds exceeded 15 knots. Before the SOP was put into effect an aircraft landed with about a 25 knot tailwind. Had all four engines in reverse and maximum brakes when they hit the addition to the runway. Again it was like jumping a street curb. The nose gear ended up inside the cargo compartment. The engineer quickly got out and disconnected the battery and stopped the sparks. This was C-130 466.

This brought a halt to operations for a few days until the Indian Military could clear the runway. The crew came back to New Delhi on an aircraft that was parked and unloading. To clear the runway was a real task. since the aircraft was on it’s nose going upslope. They got hydraulic pressure to the brakes by means of hand pumps. Jacked the nose up and put it on a cart similar to baggage carts you see at airports. Tied two long heavy ropes to the nose and had aprox.. a hundred soldiers on the ropes to swing the nose when it started to roll backward. Had a tractor behind the aircraft to pull and start it rolling. as it rolled the soldiers swung the nose of the aircraft and it rolled off the runway. Once the runway was clear we resumed operations under the new SOP. The Indian Air Force US Air Force Maintenance and Lockheed personnel, worked for several weeks putting a nose gear on the aircraft.

When it was ready to be brought back to New Delhi; I (as the Squadron Chief Pilot or whatever) was designated as the Aircraft Commander. We met in Col. Richardson’s room to discuss the procedures. I said I required two things: 1. the flight be during daylight hours and 2. the weather to be VFR. Lt. Col. Jones (39th Commander) told me to make sure all crew members wore parachutes. I told him I would; but it would be a last resort, as it was cold in those mountains. The structural engineer advised they didn’t know if the nose gear would take the beating of a take off from PSP. I told him it wouldn’t take a beating.

The next day we went to Leh in an aircraft with Col. Jones; they were to fly chase plane with us. When we got to Leh we did a thorough preflight of the aircraft. Started it up and started to taxi; when I turned the nose wheel steering left the aircraft turned right and vice versa. I taxied on the runway and lined up by turning opposite to the way you were supposed to. I seriously considered taking off that way but decided to have maintenance check it out. The hydraulic lines to the nose steering were reversed. By that time the oxygen had leaked out, and as they dragged the oxygen cart to the aircraft. the connection end of the hose was bouncing on the ground and broke off. I decided we would try again tomorrow. While we were on the runway I gave the engines a good run up. Number four prop was surging. We wrote it up and taxied back to the parking area. Got on Col. Jones Aircraft and returned to New Delhi.

When we walked into Operations Col. Jones told Lt. Col. Stewart: “Charlie you go with them tomorrow I can’t stand to watch them kill themselves”. Col. Stewart said sure. The young Lt. Navigator had gotten excited when the nose wheel steering was hooked up backward; and nearly came unglued when the oxygen leaked down so quickly, and didn’t want to go back. Mike said, ok Ralph Hatch would go. Ray Lembke heard about it and insisted he go , Ralph said whatever. So Al VanButen was the other pilot (well qualified IP) Lembke the Nav. and can’t remember the FE and LM. The antennae on the bottom of the aircraft were gone and some holes in the outer skin . Nose gear was down and welded. We decided to make it a , gear down flight. Didn’t want to raise the main gear and have it stick or something. The crew had run up to the town of Leh, the first day while the engineer and I inspected the plane; they purchased some hats . We called them BIG STOOP hats as they looked like the hats the character on Terry and the Pirates wore.

Maintenance personnel had stayed with the plane all night working on the prop, and they said it was ready to go.(The term GOOD TO GO hadn’t come into vogue at that time). We loaded up several crates of oxygen walk around bottles; they took off the other aircraft at New Delhi. Kicked the tires lit the fires and taxied onto the runway . It felt ok. Lined up on the down slope runway; held the brakes and eased the power levers to maximum. Released the brakes and was thrown back into the seat; about 100 ft down the runway, yanked the nose wheel off the ground then eased forward holding the nose wheel inches off the runway till we became airborne. Over the river; started a left turn with gear down and flaps still 50 percent. Number four prop started to surge I reduced some power on it and told the engineer to see if he could stabilize it. Van Buten whipped out the Dash One and said we can climb to 28,000 feet on three engines. I said; ok, but that's with a clean airplane, gear and flaps up; as long as we are getting positive thrust we will keep it going.

At altitude we were on oxygen hooked up to walk around bottles in our laps. Lembke said my bottles empty pass me up another, He said Dave how you doing. I said ok. He looked at my hose and it was crimped so we straightened it out. When we cleared the mountains and descended to 10,000 ft. and as power was increased Ole 4 started to surge; so we shut it down. I told the crew I waited till we got to this point ; see the airfield off to the right if it didn’t feath er we would have tried to land or control crashed at that Indian Air Force Base. Our VHF radios were out. We contacted the Combat Control Team (CCT) by UHF and advised of our Estimated Time Of Arrival (ETA) and to notify the tower as we had no VHF. Also requested the Flight Surgeon meet the aircraft with combat rations. CCT replied the Doctor had gone to Agra to visit the Taj Mahal. Then Barry Howard came on and said he would fill in for the Doc. Col. Stewart caught up about that time and said Dave it wasn’t that bad; to which I replied you weren’t with us the first forty five minutes. They passed us as we were, 3 engine gear down and flaps 50 percent. He said: Dave I will land first and relay instructions from the tower, that way in case you crash and close the runway I won’t have to divert. He said the tower gave me the choice of runways we were landing to the East. I told him we would take the old runway on the left, that way we wouldn’t tie up the main runway.

Lembke advised the engineer to put his feet on the pedestal in case the nose gear collapsed, ( an engineer got his foot broken when a B Model ran off the runway at Ramstien, and the nose gear collapsed). We made the usual paint job of a 50 percent flap landing; held the nose gear off the ground, reversed the 3 engines and slowed down to less than 50 knots when the nose gear touched. The warning horn beeped and we all held our breath; expecting to hear scraping metal but is was ok. We taxied into the parking area right by the Hangar; put on our BIG STOOP HATS and shut down the engines. Col. Jones came bouncing up on the flight deck. He said” I got Evreux on the radio; they want to know if you made it all right”. I turned around and gave him my BIG STOOP toothy grin and said in a serious voice: “COLONEL; YOU CAN TELL EM WE MADE IT”. I guess he saw the obvious answer was yes , as he turned away and said awe shit, as he hurried off to report.

I got to fly this aircraft 4sick sick (66 was the last 2 numbers) when I rotated back to Evreux. They had Patched the holes, fixed the radios, oxygen system, prop etc. and even faired over the nose wheel well. The nose wheel was down and welded but the main gear was retractable, and we could pressurize, on the flight to Evreux. I heard later that the IAF had done such a good job the nose gear was probably structurally stronger than before.

AIR DROPS IN INDIA

About the time the C-130 had the runway at Leh tied up, we started air drops in the Himalayas. The Indian military needed a lot of supplies and didn’t have parachutes, or a way to recover them from the remote valleys in the Himalayas. A survey team had flown up to the area in an Indian aircraft and looked at the area from the air. They had made up some procedures for free fall dropping supplies from 300 feet above the ground. The valley we were to drop in was aprox.. 11,000 feet above sea level. At higher altitudes the air is less dense and that means the true air speed is faster than the indicated airspeed. So we were to drop at 130 knots indicated airspeed, with 50 percent flaps down. this would give the aircraft a slightly nose high attitude. I and Roy Smith (an IP) were the pilots on the first drop mission at this new area; using the free fall, gravity extraction Method.

The load on the first drop was concertina barbed wire tied down on plywood skid boards; weighing 28,000 pounds. The 5th Aerial Port load masters had rigged a pilot chute, that when released would open behind the aircraft and cutting blades would cut the nylon web restraining gate. With the nose high attitude; the load would roll off the back of the aircraft. and fall 300 feet to the ground. Then the Indian army would pick up their supplies. We joked about how we would hate to have the job of policing the drop zone with barbed wire strewn over it. One of the personnel from the survey team went with us to point out the valley and DZ. On the way up he said,”turn around we just passed it”. I said what do you mean? He said turn now that next valley is Red China Territory. So we made a 180 degree turn. Found the right valley and he pointed out the drop area.

The procedures call for us to descend to 300 feet and slow to drop speed and dry run the DZ. to see if any personnel were in the danger zone. I did so and when I started to turn left the terrain started to rise. I added power and had full power and we were skimming the ground as we completed the 180 degree turn. I said that’s the first procedure we will change; dragging the DZ. at slow speed and low altitude at this height is too dangerous. They can see well enough at higher speed and altitude.

We started our run into the DZ. and descended to drop altitude, opened the rear ramp and at the designated point released the pilot chute, and waited.

It took a few seconds (that seemed like eternity) before the load started to roll. when it did the center of gravity changed and the control column hit me in the chest, the nose was extremely high, I had both hands on the yoke and told Smitty help push. We were both pushing with all our might, then the load departed the aircraft. It felt like we had passed a watermelon. We were both pulling back as the nose now was down and headed for the rocks. Holy mackerel what a ride; space mountain had nothing as exciting. We headed back to New Delhi. I said the first thing we will recommend changing is the maximum weight for free fall loads. Which were cut down to aprox. 18,000 pounds and dry runs to clear DZ, were made at higher airspeeds and altitudes.

The US couldn’t keep using up pilot chutes to release the aft restraint webbing to allow the loads to roll off the back end of the aircraft. I don’t know who; but the load masters came up with a manual means of releasing the rear restraint webbing. By sewing large metal rings on the ends of the webbing and using the tie downs on each side with a small length of cargo chain through the ring and a nylon line to the front of the cargo compartment on each side. At the green light (release Point); the load master would pull the nylon cords; which released the tie downs allowing the chain to slip through the rings. and the load would roll off the aircraft. This to me was the epitome of American GI ingenuity. We continued making drops using this method for quite awhile.

A DZ was also established up the valley from Leh that we dropped containers on; since the chutes could be trucked to Leh, returned to Delhi and reused.

One day Leon McGoogan and I were returning from a drop mission; Mac was in the pilots seat. We landed on the parallel runway nearest Squadron Operations. On rollout the plane shook very violently. I said hold ‘er in the road newt she's a rarin'. As we came to a stop on the runway we knew we had a flat tire on the right side. The wind was blowing from the left and with the right wing down; the wind was lifting the left wing. We called for a tire change crew. The engineer ran outside and turned the number 4 prop to keep it from touching the ground. we got off the airplane and the right wing continued to sink lower. It looked like it wanted to roll over on it’s back. Col. Jones came up and said “is it gonna roll over”. I said looks like it may. He said” DAMN IT DAVE YOU’RE THE CHIEF PILOT IS IT GONNA ROLL OVER”. At this point I ran over to the external fuel tank on the right wing ; which was down to chest high, grabbed it and yelled “NOT IF I CAN HELP IT COLONEL!!! He looked at me and said awe shit. It didn’t roll over. The tire was changed and no other damage done.

A lot of corners were cut to get the job done and this bothered some of the pilots. The Indian Air Force invited our officers to their Officers Club for a party.

And as usual the pilots migrated to the bar and talked about flying. One of the Instructor pilots was drinking a little heavily and was upset at the regulations that were being bent to the breaking point. Col. Stewart came up and said we are the guests of the Indian Air Force how about mingling. At which point the IP turned and kicked as Col. Stewart was walking away; barely missing his rear.

I told the guys ok let’s mingle. The plastered IP didn’t respond. I coaxed him over to a table and he was getting obnoxious. Col. Jones came over and said “Dave get him out of here”. He was a lot bigger than either of us and I felt like saying:’ if you want him out ; you throw him out’. We had another drink and I finally tricked him into going back to the hotel. When I opened the door and he realized he was in his own room; he went to slap me on the back, I ducked and he spun onto the bed. I put his feet on the bed and went out. The next day he acted like he didn’t remember and I didn’t mention it again.

Thank goodness no one had an accident while cutting corners to get the job done. Although every one did it; you sure couldn’t expect anyone to stand up for you if it turned out bad. I was asked to fly with a young pilot from the other squadron and see if I could get him to land on the runway at Leh. He would touchdown about 100 feet short of the runway every landing. Several people had noticed it and were afraid the PSP might come loose and cause a bad accident. That day I rode in the copilots seat up to Leh and told him to touch down on the runway not short. He knew he was touching down short and was doing it on purpose. I told him to just show me he could land on the runway.

The weather was iffy on the descent but we could see the chutes on the DZ, on the way down the valley and continued on. He made a good approach and landing on the runway. While offloading the weather closed in and we couldn’t see the mountains around the valley. I got on the radio and called any other inbound to Leh and advised the weather was rotten. One inbound wanted to know why we're on the ground if it was so bad. I told him we were waiting for a sucker hole to pass over. That particular aircraft diverted back to New Delhi.

We waited for a sucker hole to come and when I could see blue sky through it straight up we took off. I was in the pilots seat and over the valley started a climbing left turn. Keeping the airfield in sight till we reached 23,000 feet. Then asked the navigator for a heading back to Delhi. He said where the hell are we? I said look out the left window we are over the airfield at Leh. He said ok and gave me a heading. I apologized to the crew for not telling them my intentions before take-off. But didn’t have time or we would have missed the hole moving by. I complimented the crew on their performance and especially the aircraft commander on his landing at Leh.

The 322nd AD / 317 TCW kept a Squadron on Rotation in New Delhi flying missions into the Himalayas for over six months. At that time the C-130A was the ideal aircraft to accomplish this type mission. Even today the ideal aircraft would still be a version of a C-130.